QTMS

Through continuous measurements from vehicles in traffic, we automatically deliver quality-assured information to the railway owner's system. This enables the prevention of traffic-affecting faults, cost-effective maintenance and a more sustainable railway infrastructure.

"QTMS is like an ECG that reads the tracks"

Solutions - How QTMS creates value for track owners

QTMS helps track owners digitise condition-based maintenance through continuous measurement and analysis of track condition parameters. Our solution focuses on reducing traffic disruption by identifying problems in time and delivering insights that enable the right actions to be prioritised.

-

Continuous track status from trains in service

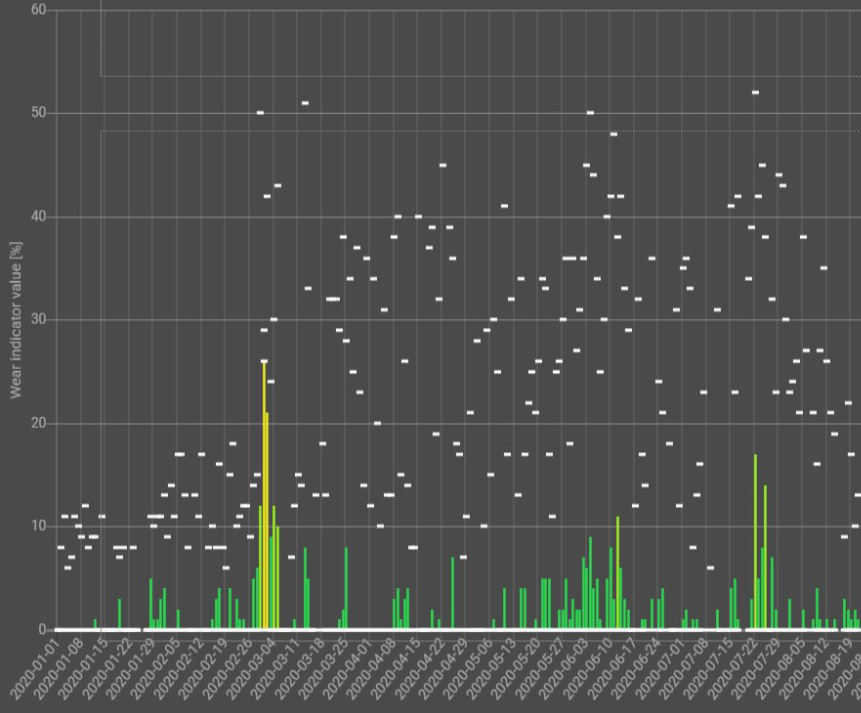

Automated measurement according to SS EN 13848, with insights into rates of change and trends. .

-

Preventive maintenance

Reduces the need for corrective maintenance by providing the basis for predictive actions. -

Impacts and benefits

QTMS complements measurement trolleys through frequent data collection, reducing the need for manual inspection and improving the accuracy of planning.

Services - How QTMS works

QTMS is a complete service that manages the entire process from the installation of hardware to the delivery of insights and actionable recommendations.

QTMS services in five steps:

-

Installation: Sensors and other measurement technologies are installed on locomotives and trains.

-

Data collection: Continuous measurement of track parameters around the clock.

-

Analysis: Data is quality-assured and processed to generate insights and trends.

-

Delivery: Automated alarms and reports are created for predictive maintenance.

-

Take action: Data is transformed into concrete action proposals that facilitate decision-making.

Measurements of track parameters according to industry standard

QTMS continuously measures track condition to enable condition-based maintenance and prevent problems before they affect traffic. By collecting high-quality data directly from trains in service, we create a detailed picture of the railway infrastructure. Our measurements follow industry standards and help reduce unplanned stops and improve safety and comfort.

FAQ

Do you have questions about how QTMS can solve common challenges in railway maintenance? From data quality and integration to how our insights can reduce traffic-impacting errors, we can answer your questions.

Our history

QTMS has its roots in a research project from 2013 that was developed into a commercial product in 2017. Today, QTMS is used by track owners such as the Swedish Transport Administration and the Stockholm Region Transport Administration to streamline and improve railway maintenance.

.png)