QTMS

We are convinced that more and better quality data provides a better basis for decision-making and is one of the key elements in taking control of track maintenance.QTMS therefore becomes an invaluable source of data and a powerful tool that provides a better basis for decision-making than ever before. We also believe that it is important to measure parameters that are already defined and can be used to act on.

Take the step towards predictive maintenance where you can reduce your costs by 20%, that's a huge amount of money to save, all the time, every year.

A support system like QTMS is the tool of the future to find defects and fix them before they grow large

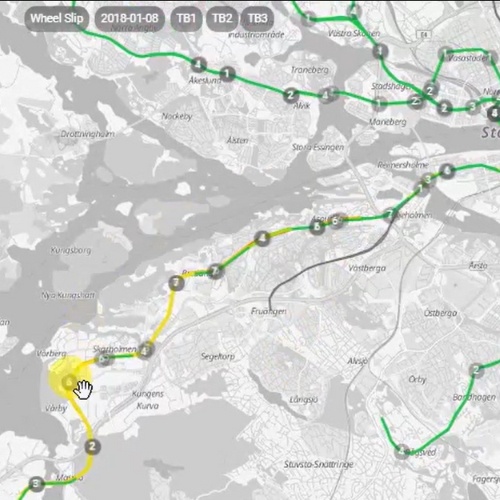

Real-time monitoring of the track

Thanks to QTMS' unique analysis and AI, the characteristics of the sensor signals are analyzed and then specific track defect is identified. The AI can be improved over time to increase the accuracy of the analysis.

QTMS measures the condition of the rails, fasteners and substructure and collects large amounts of data. It even allows us to distinguish irregularities from the wheels and rails so that we know which part needs to be fixed and exactly where.

-

Track Decay Rate

-

Track Roughness

-

Wheel Slip

-

Severe Wear

-

Curve Squeal

-

Rail Buckling

High quality data for better decisions

(QTMS) provides high-quality, real-time data that gives a comprehensive overview of track conditions. This precise data input enables informed decisions based on timely and accurate information, resulting in more effective and targeted action.

Prioritize the right actions

By pinpointing exactly where, when, and what type of maintenance is required, maintenance teams can prioritize the actions that have the greatest impact on safety and reliability.

QTMS facilitates the allocation of resources to the most critical maintenance needs, optimizing both time and budget.